Hailper is sparking a quiet industrial revolution through the transformation of non-standard automated production lines. While the global manufacturing industry has achieved an average automation rate of 35%, over 60% of small and medium-sized enterprises (SMEs) in China are still mired in the “labor-intensive” stage. With labor costs rising by an average of 12% annually, order delivery cycles extending by 30%, and product defect rates remaining stubbornly high… Behind these figures lies the sleepless anxiety of countless business owners. The solution may well lie in the “transformation of non-standard automation production lines.”

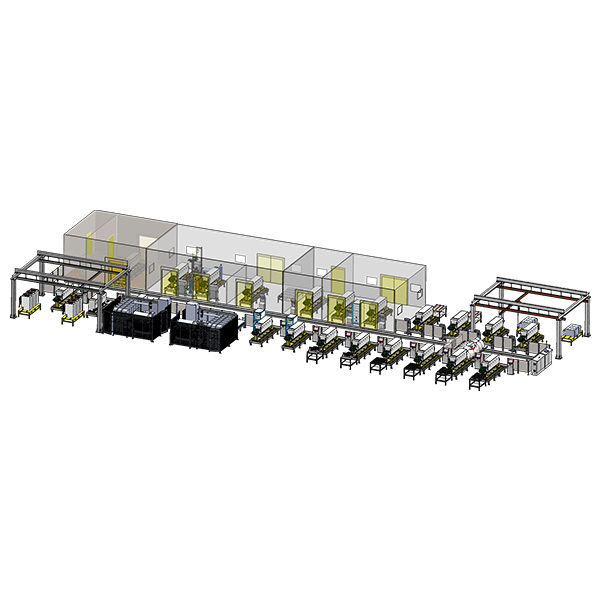

Amid the wave of transformation and upgrading in the manufacturing sector, non-standard automation equipment has emerged as the go-to solution for many enterprises seeking to enhance production efficiency and streamline process flows, thanks to its flexibility and performance. Take the case of a BYD automotive parts manufacturing enterprise’s non-standard automation equipment transformation. Initially relying on manual assembly lines, the company decided to introduce non-standard automation equipment due to escalating labor costs and inconsistent quality control.

The upgraded non-standard automation equipment integrates high-precision sensors, intelligent robots, and automation control systems, enabling fully automated line operations from raw materials to finished products. Through the use of robotic arm grasping, automated visual inspection, and an intelligent logistics sorting system, the product defect rate has been effectively reduced, and production efficiency has increased by approximately 30%. Additionally, the system features data collection and analysis capabilities, providing enterprises with production data analysis support to further optimize production processes and achieve lean production management.

Non-Standard Automation Production Line Transformation: Double Your Production Efficiency!

The successful implementation of non-standard automation equipment has not only significantly enhanced the production efficiency and product quality of the enterprise but also mitigated safety risks associated with manual operations. This case demonstrates that the rational application of non-standard automation equipment is a crucial pathway for promoting the transformation and upgrading of the traditional manufacturing industry and achieving intelligent manufacturing.

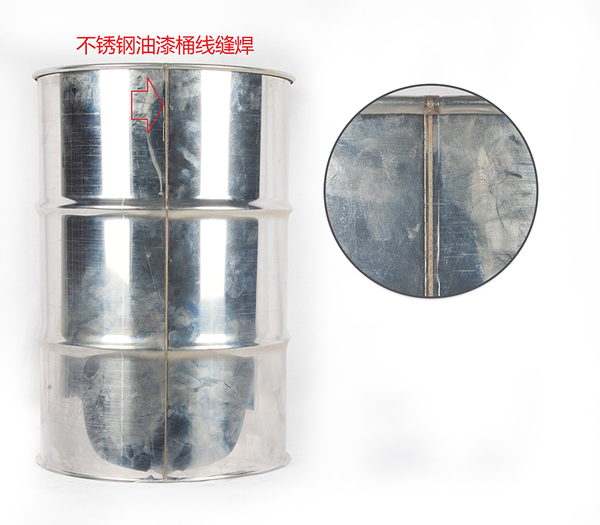

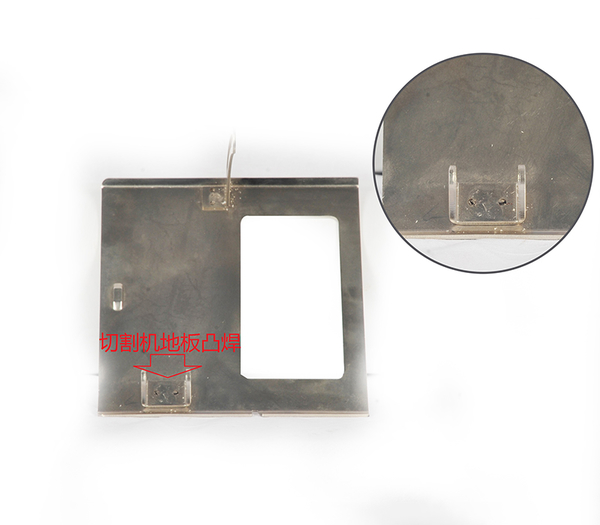

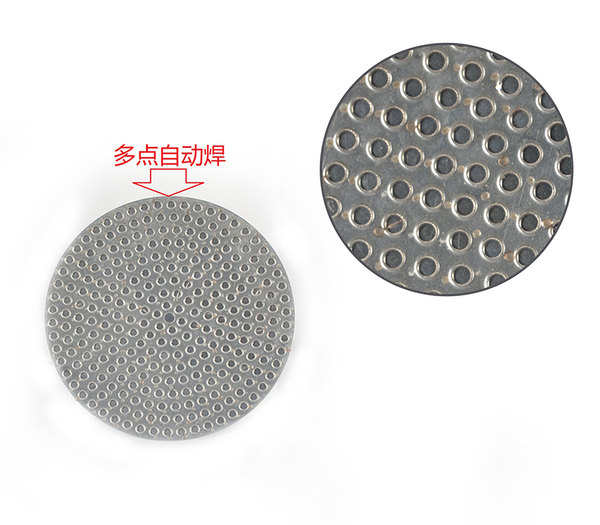

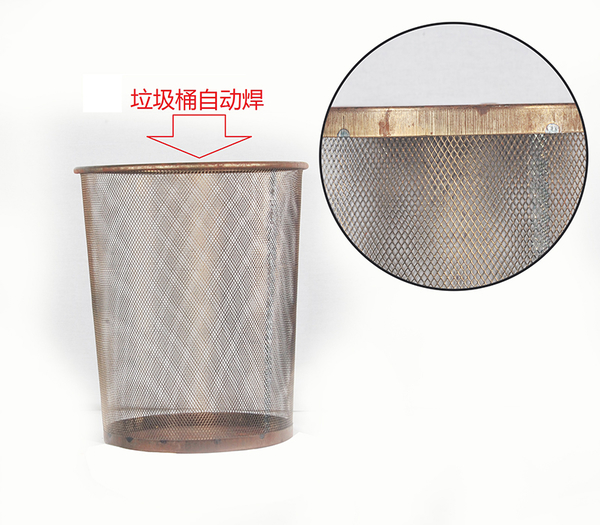

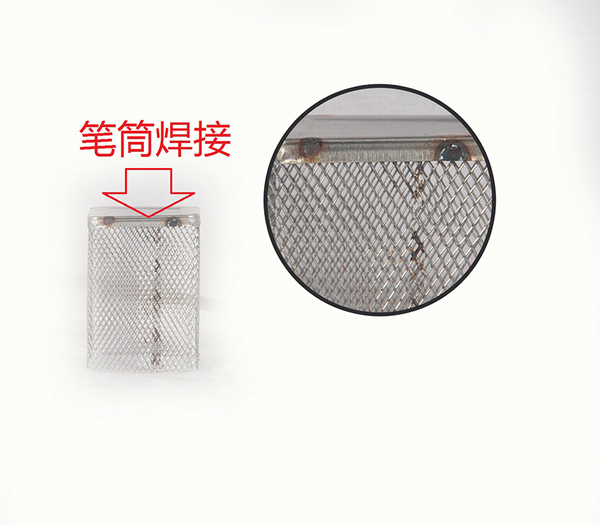

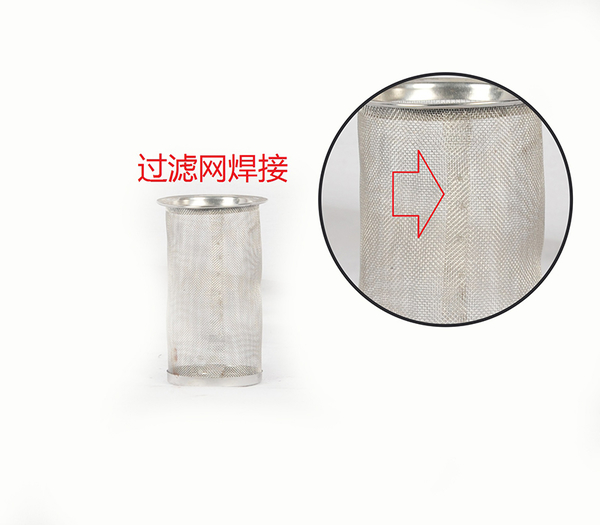

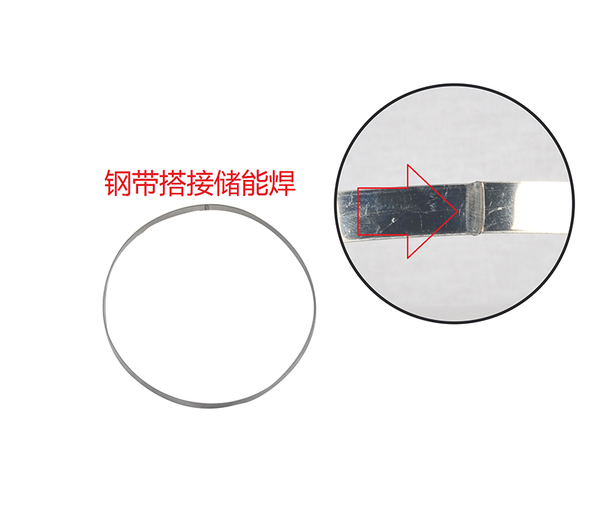

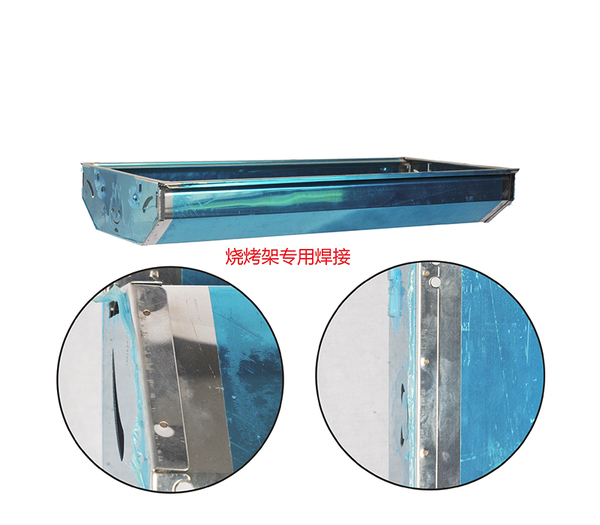

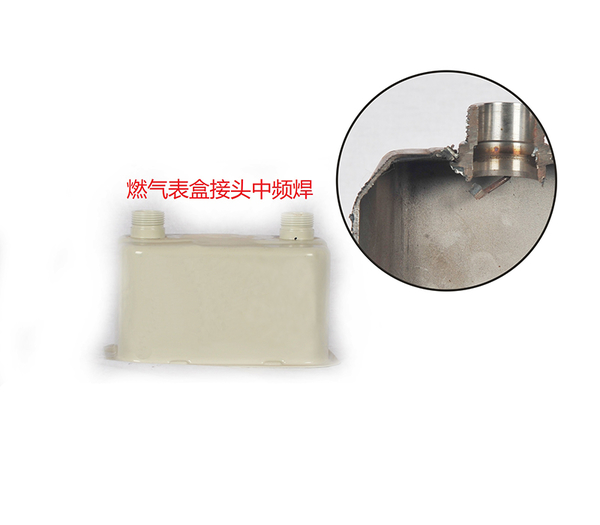

Our resistance welding machines include spot projection welding, butt welding, and lap joint welding.

In metal processing, we are also skilled in induction heating equipment for metal tempering, brazing, and melting.

Metal wire forming equipment, used for straightening metal wires, 2D forming, 3D forming, and circular forming.

Leave a Reply